top of page

APIE MUS

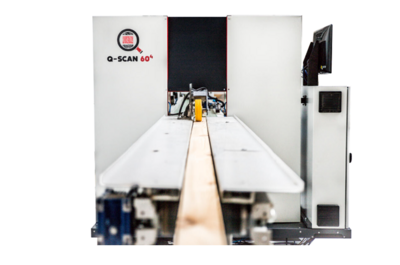

Esame ilgametę patirtį turinčių inžinierių komanda, užsiimanti CNC staklių bei įrenginių tiekimu Lietuvoje. Mūsų atstovaujama įranga užtikrina kokybišką ir optimizuotą įvairių medžiagų frezavimą, skenavimą ir apdirbimą. Daugybė įmonių Lietuvoje bei užsienyje (Lenkijoje, Čekijoje, Amerikoje, Kanadoje, Švedijoje, Prancūzijoje ir kt.) jau pasirinko mūsų atstovaujamą įrangą ir tokiu būdu padidino savo produkcijos gaminimo našumą bei sumažino sąnaudas. Įmonės renkasi būtent mūsų komandos atstovaujamą produkciją dėl protingo kainos ir kokybės santykio, dėmesio klientams bei profesionalumo.

bottom of page